HYDROCARBON RUBBERS

-

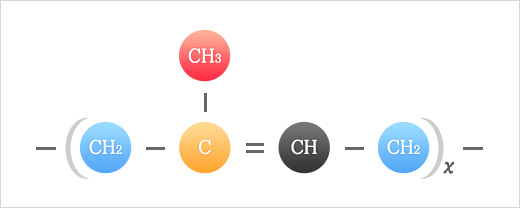

Natural Rubber, Polyisoprene

Abbreviation NR, IR Density(g/cm³) 0.91 tg(˚C) -75 Service Temp.(˚C) Max. 70 *Properties : Good inherent tack, high tensile, good hysteresis, good hot tensile and hot tear properties.

-

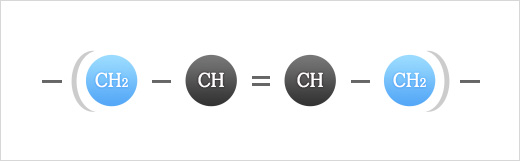

Polybutadiene

Abbreviation BR Density(g/cm³) 0.90 tg(˚C) -85 Service Temp.(˚C) Max. 70 *Properties : High resilience, good low temperature flexibility, good flex fatigue characteristics and high abrasion resistance.

*Trade Name : Synpol(Ameripol), Budene(Goodyear), Buna CB(Mobay Chem.), Taktene(Polysar)

-

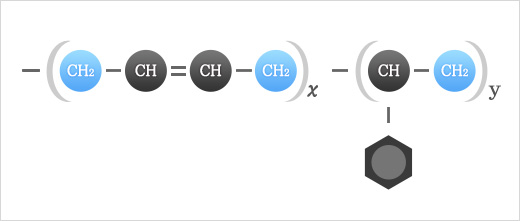

Styrene-butadiene

Abbreviation SBR Density(g/cm³) 0.93 tg(˚C) -55 Service Temp.(˚C) Max. 70 *Properties : The most widely used rubber in the word is SBR. At present, SBR constitutes about 40% of the total synthetic rubber consumed in the United States. It has good abrasion resistance.

-

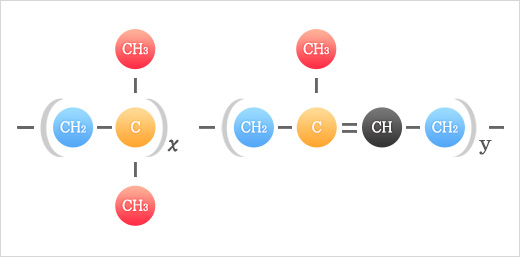

Polyisobutylene

Abbreviation IIR Density(g/cm³) 0.92 tg(˚C) -65 Service Temp.(˚C) Max. 100 *Properties : Low rates of gas permeability, thermal stability, ozone and weathering resistance, vibration damping and higher coefficients of friction, chemical and moisture resistance.

-

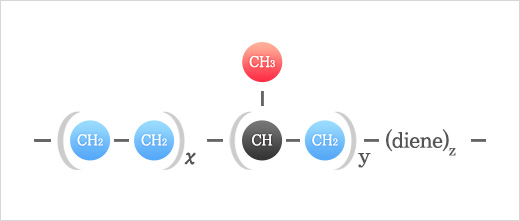

Ethylene-propylene

Abbreviation EPDM Density(g/cm³) 0.87 tg(˚C) -55 Service Temp.(˚C) Max. 150 *Properties : Since the terpolymers are highly saturated, the compounds have excellent resistance to ozone and oxidation without the use of any antidegradants.

*Trade Name : Epsyn(Copolymer Rubber), Keltan(DSM), Nordel(DuPont), Royalene(Uniroyal Chem.), Vistalon(Exxon)