SPECIALTY RUBBERS

-

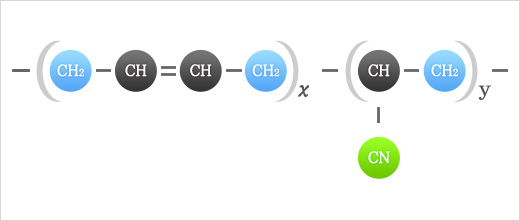

Nitrile

Abbreviation NBR Density(g/cm³) 0.98 tg(˚C) -40 Service Temp.(˚C) Max. 70 No.03 oil swell(%) Max. 40 *Properties : Good strength properties, excellent oil and gasoline resistance, abrasion resistance, gas permeability and thermal stability which stem from the highly polar character of the acrylonitrile group.

*Trade Name : Chemigum N(Goodyear), Hycar(BF Goodrich), Krynac(Polysar), Nipol DN(Nippon Zeon), Paracril(Uniroyal)

-

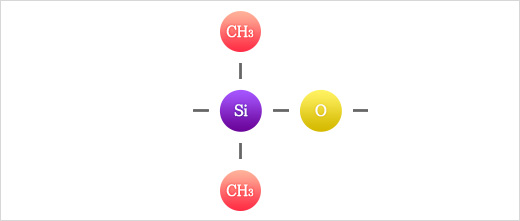

Silicone

Abbreviation MQ(VMQ, PMQ, PVMQ) Density(g/cm³) 0.98 tg(˚C) -110 Service Temp.(˚C) Max. 225 No.03 oil swell(%) Max. 80 *Properties : Wide Temperature range(-65˚C to 315˚C), flexibility at lower temp(to -100˚C), lower level of combustible components, excellent dielectric properties, lower compression set, body tolerance(bio-compatible), neither kill nor support the growth of fungus, radiation resistance, thermal ablative, release(prevent adhesion of sticky materials) which stem from the unique molecular structure.

*Trade Name : SE(G.E), Rhodorsil(Rhone-Poulenc Inc) Silastic(Dow Corning)

-

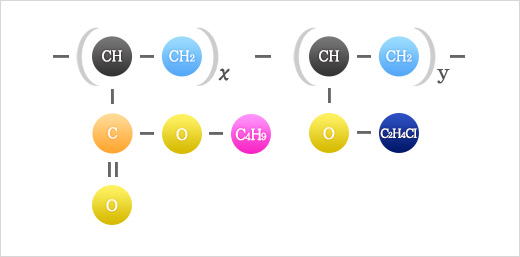

Polyacrylate

Abbreviation ACM Density(g/cm³) 1.13 tg(˚C) -30 Service Temp.(˚C) Max. 170 No.03 oil swell(%) Max. 60 *Properties : No unsaturation in the backbone offers superior resistance to heat, ozone & ultraviolet light and the very polar acrylate group not only develops oil resistance but also is resistance to crosslinking by sulfur-bearing lubricants.

*Trade Name : CYANACRYL(American Cyanamid), HYCAR(Nippon Zeon), KRYNAC(Polysar), Nipol AR(Goldsmith & Eggleton)

-

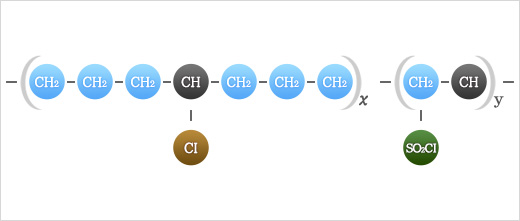

Chlorosulfonated Polyethylene

Abbreviation CSM Density(g/cm³) 1.18 tg(˚C) -50 Service Temp.(˚C) Max. 125 No.03 oil swell(%) Max. 80 *Properties : Excellent weathering resistance, high tensile, excellent abrasion resistance, excellent resistance to corrosive chemicals, good oil & grease resistance and excellent electrical properties.

*Trade Name : HYPALON(DuPont)

-

Polychloroprene

Abbreviation CR Density(g/cm³) 1.23 tg(˚C) -50 Service Temp.(˚C) Max. 100 No.03 oil swell(%) Max. 120 *Properties : Classified as general purpose, adhesive or latex types and the formal types are used in a variety of elastomeric applications. G types contain copolymerized sulfur, provide the optimum in adhesion to fibers, flex resistance, strength and resilience and are most suited for dynamic applications. W types have excellent uncompounded stability and can be milled without sticking over a wide temp. range. Compression set can be met with W type compositions. T types are generally better processing than G and W types due to its highly crosslinked microscopic "gel" form.

*Trade Name : Neoprene(DuPont), Butaclor(A Schulman), Denka Neoprene(denka)

-

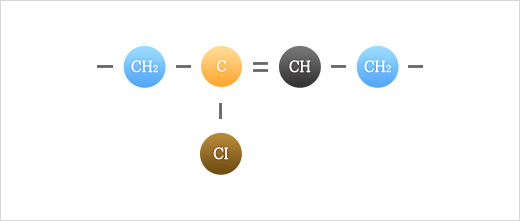

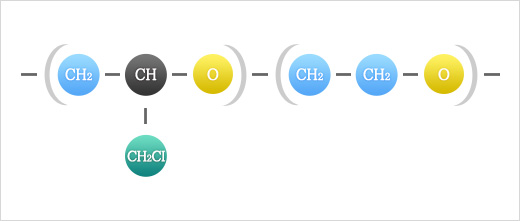

Epichlorohydrin

Abbreviation ECO Density(g/cm³) 1.27 tg(˚C) -45 Service Temp.(˚C) Max. 125 No.03 oil swell(%) Max. 30 *Properties : The combination of fuel resistance, air aging excellent low temperature flexibility and moderate cost is assured a large market in the automobile industry.

*Trade Name : Gechron(Goldsmith & Eggleton), Herclor(Hercules), Hydrin(BF Goodrich)

-

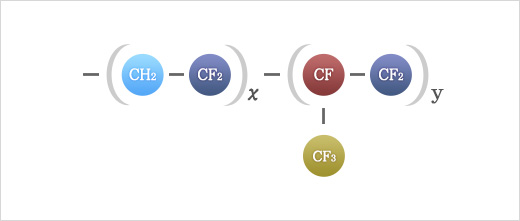

Fluorocarbon

Abbreviation FKM Density(g/cm³) 1.82 tg(˚C) -30 Service Temp.(˚C) Max. 250 No.03 oil swell(%) Max. 10 *Properties : Used in a wide varienty of high-performance applications because they provid premium performance and long-term reliability even in harsh environments. Their exceptional resistance to heat aging and a broad range of fuels, solvents and chemicals makes them ideal for many demanding aerospace, automotive and industrial applications.

Cure systems of Diamine, Bisphenol & Peroxide must be selected appropriately to their physical properties required.*Trade Name : VITON(DuPont), FLUOREL(3M), TECHNOFLON(Montefluos), DAI-EL(Daiken)

-

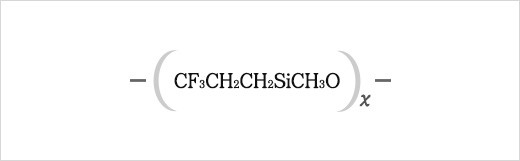

Fluorosilicone

Abbreviation FVMQ Density(g/cm³) 1.43 tg(˚C) -70 Service Temp.(˚C) Max. 235 No.03 oil swell(%) Max. 20 *Properties : The addition of fluorine to the alkyl groups of silicone elastomers develops elastomers with a high degree of solvent resistance and excellent low temperature capabilities.

-

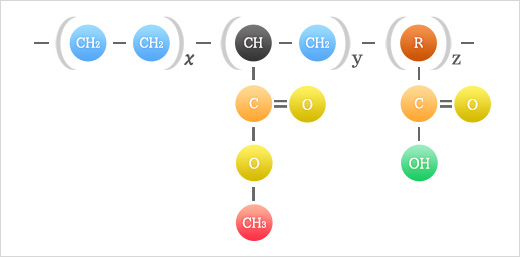

Ethylene-Acrylic Rubber

Abbreviation AEM Density(g/cm³) 1.25 tg(˚C) -30 ~ -35 Service Temp.(˚C) Max. 180 - - *Properties : AEM's resistance to ozone and weathering is superior to nitrile rubber (NBR) and its cold temperature performance is better than that of ACM's. Excellent heat and ozone resistance, AEMs have outstanding vibration dampening and good dynamic and abrasion properties over a wide temperature range.

*Trade Name : VAMAC(DuPont)